AMT Innovations is proud to release our new patented (US 9289869) workholding line of products, Get-A-Grip®.

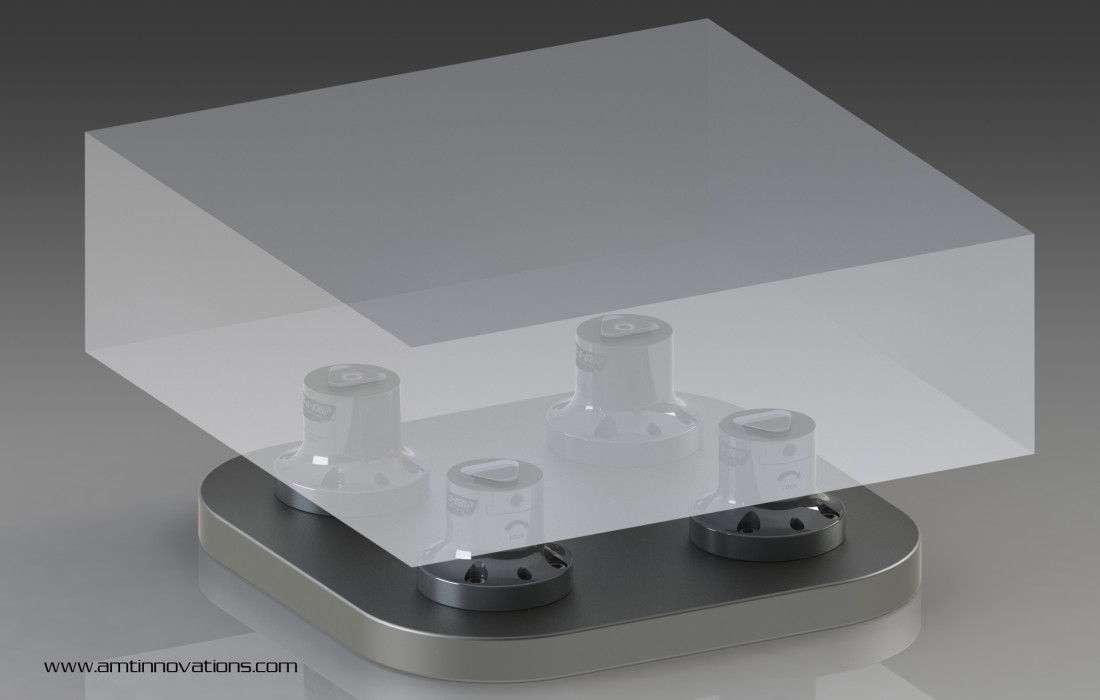

Get-A-Grip® is a standard product line of 4 and 5-axis workholding solutions. While these solutions have been developed mostly for multi-axis CNC milling, they also offer advantages for common 3-axis CNC machining work and even 2-axis CNC turning.

Flexible product options allow users to apply this technology to palletized 4-axis horizontal CNC mills with tombstones, 5-axis CNC machines as well as CMM fixtures.

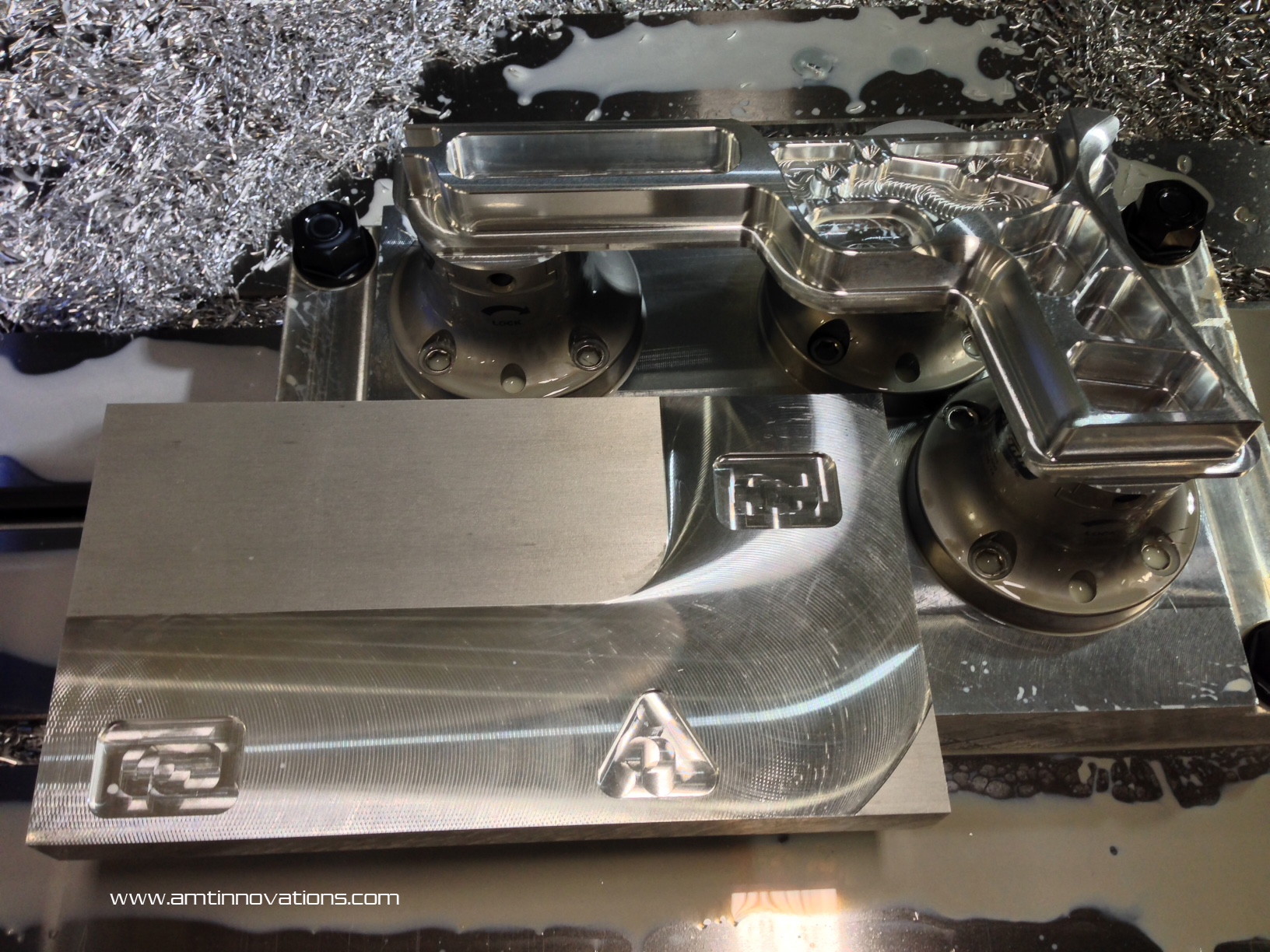

The Stainless Steel™ Logo seen above is a trademark and badge of the build quality this product offers. The use of robust materials and innovative design elements bring flexibility and time-saving benefits to our customers which will result in a dramatic increase in production and profits.

Please check back for the new models and accessories in the upcoming months.

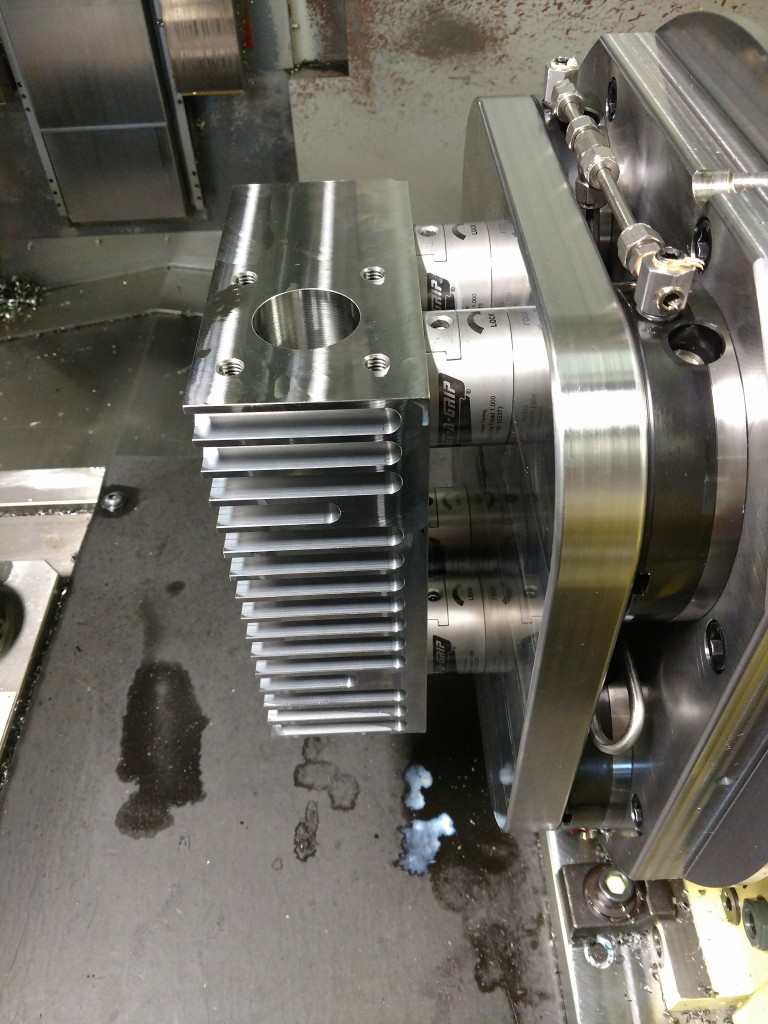

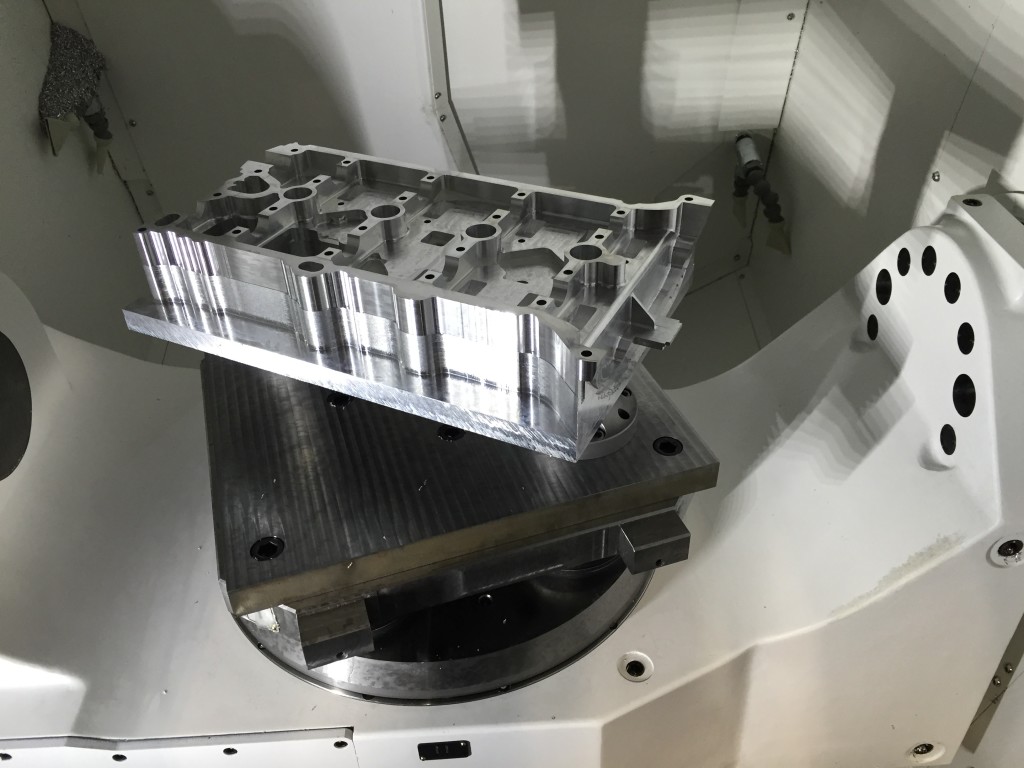

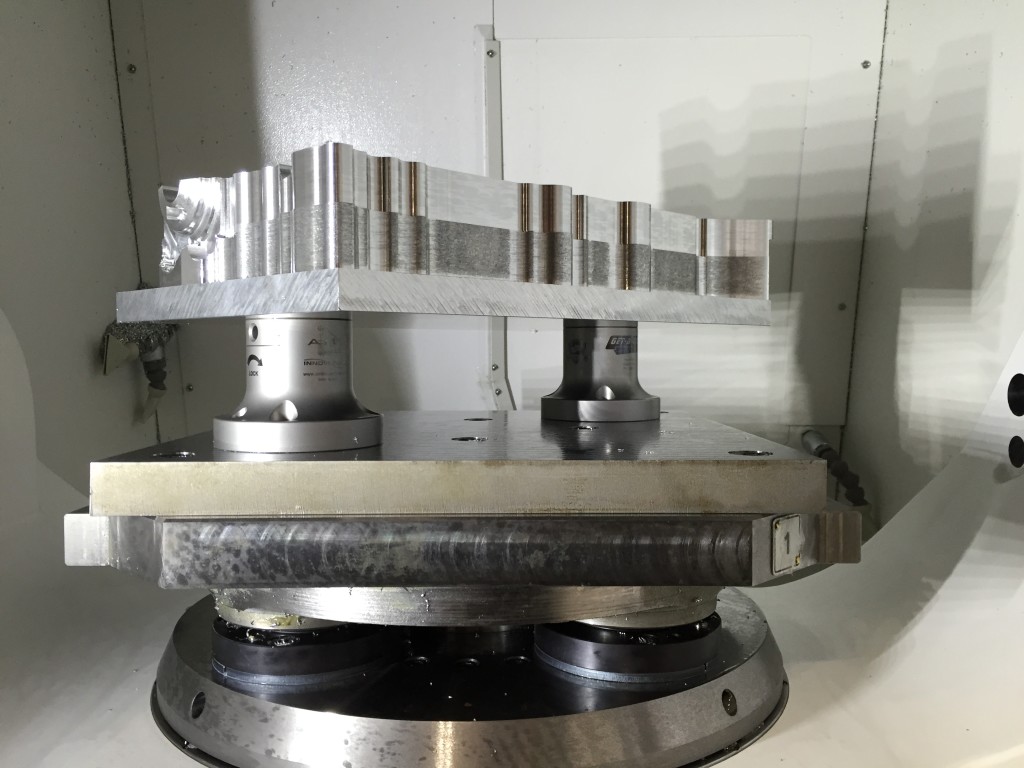

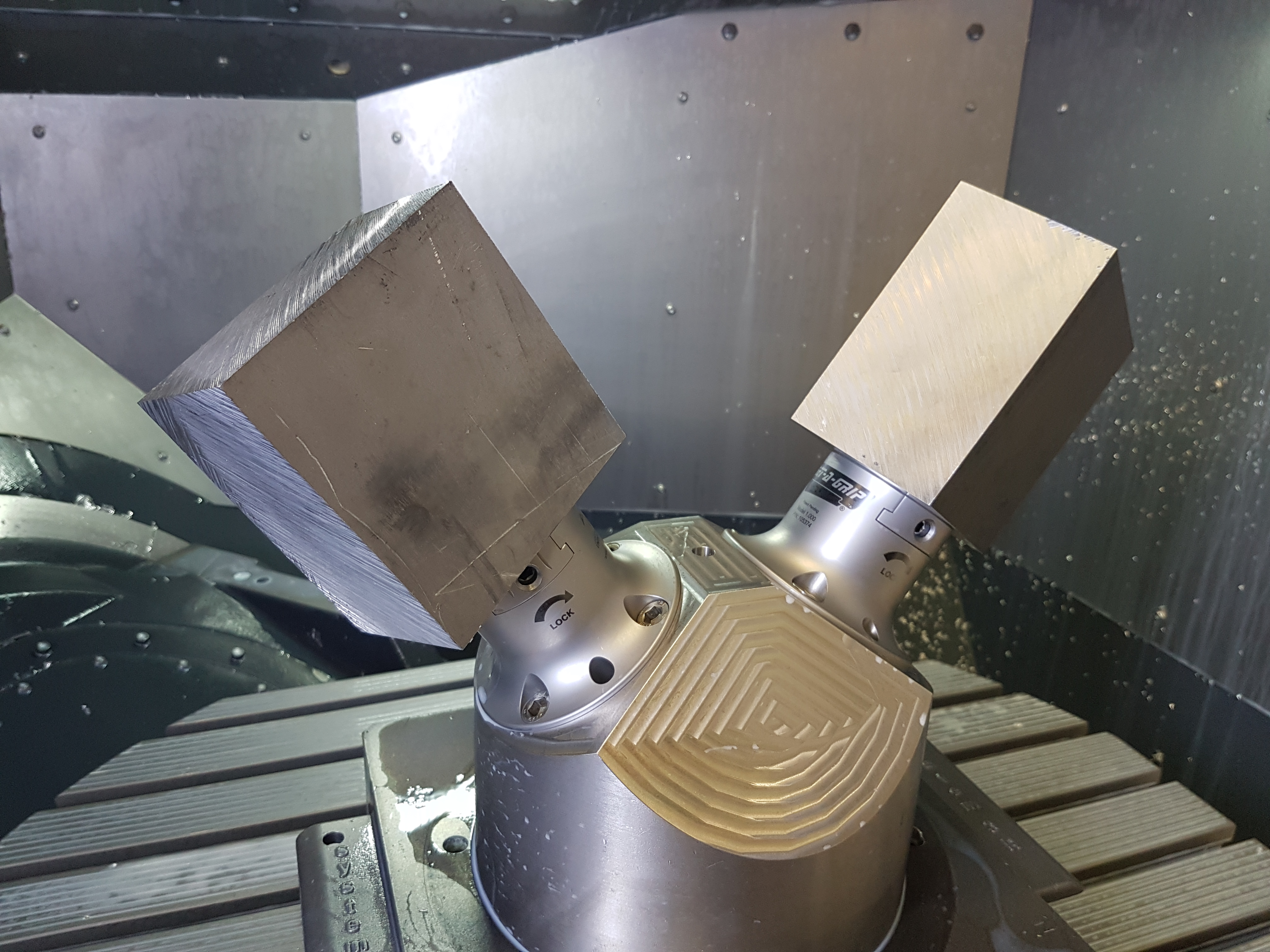

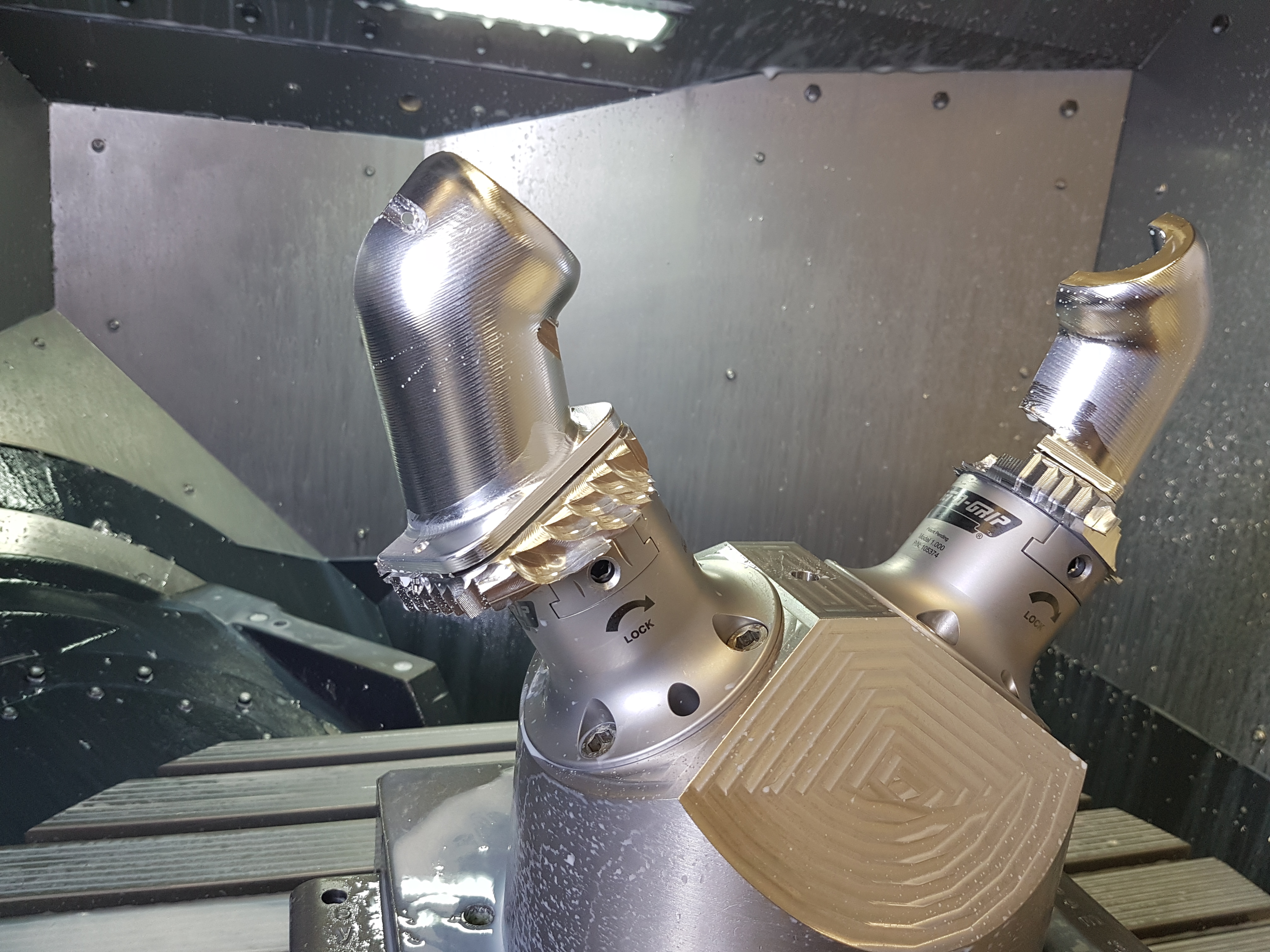

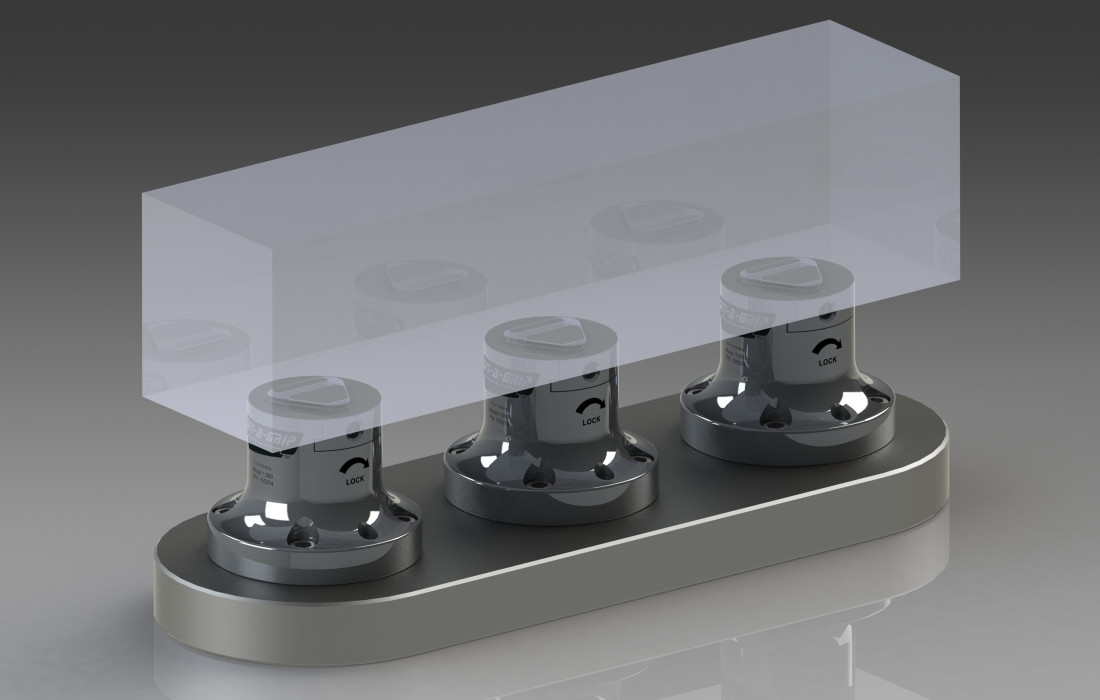

5-Axis Workholding Fixture Get-A-Grip in Action:

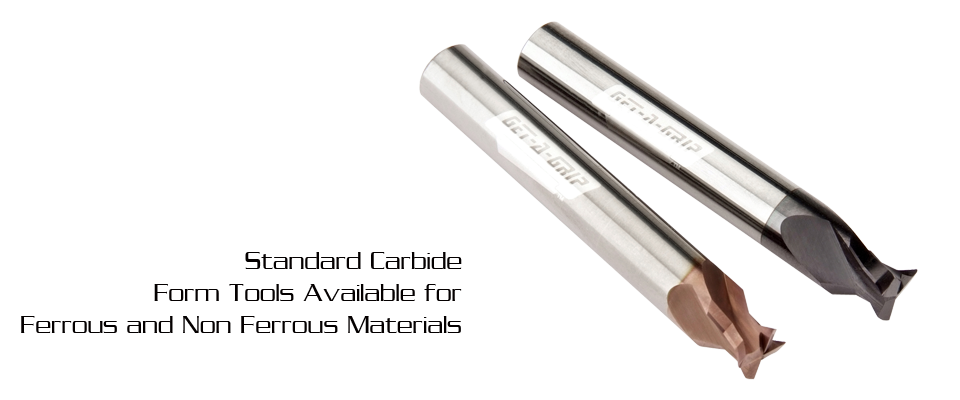

Get-A-Grip Features:

- Robust, Hardened, Stainless Steel Construction

- Positive Clamping / Un-Clamping (No Reliance on springs)

- Single clamp screw

- Precision clamp slide

- Unlike competitive products, the dovetail / clamping geometry does not distort or deform workpiece

- Triangular contact geometry eliminates the need for an indexing pin

- Triangular dovetail geometry provides 3 evenly spaced, radial force vectors for superior gripping

- Clamping geometry allows for excellent repeatability in part removal and re-clamping

- Available in modular and non-modular configurations for greater flexibility

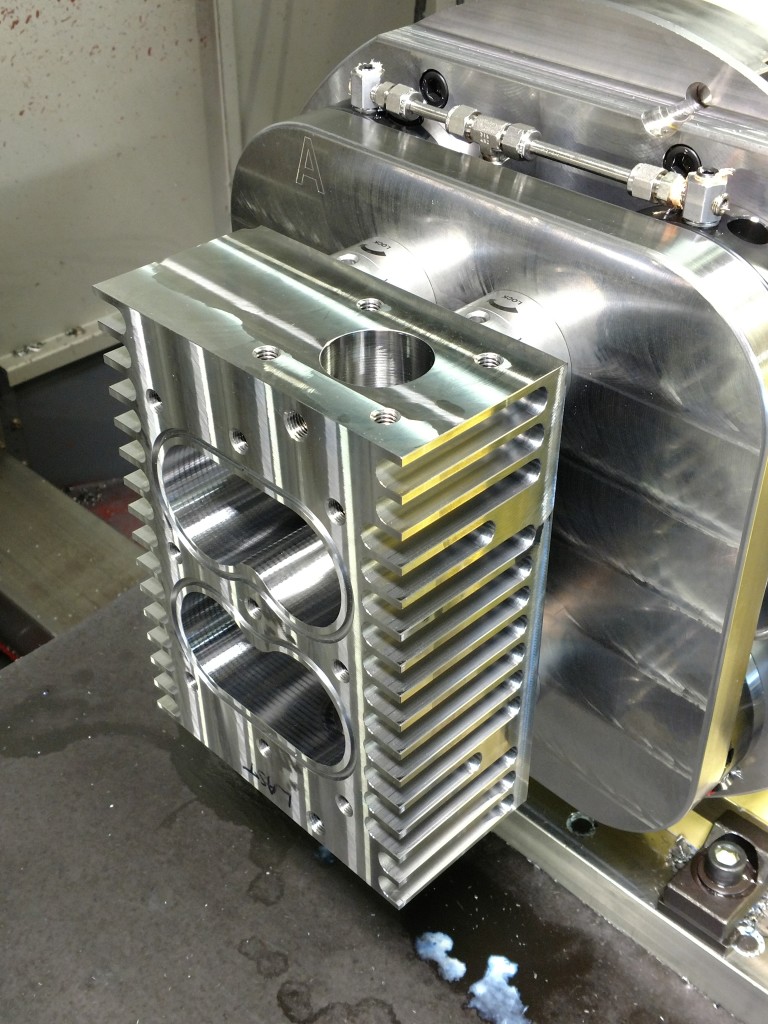

- Multiple models and configurations to hold large parts

- Internal clamping geometry reduces material preparation area and can be strategically placed where the finished part may have a pocket which greatly reduces secondary operations

- Precision tolerances and fixture locating features

- 3D CAD (Solidworks) Models available

- Made in USA

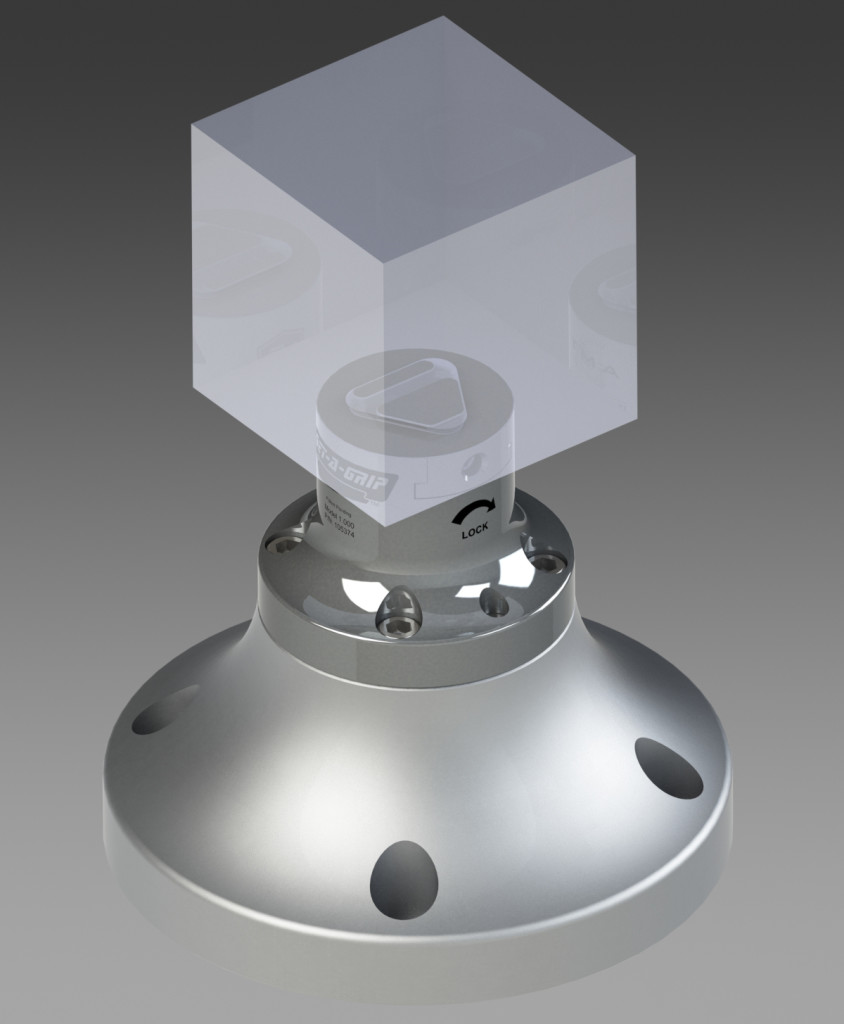

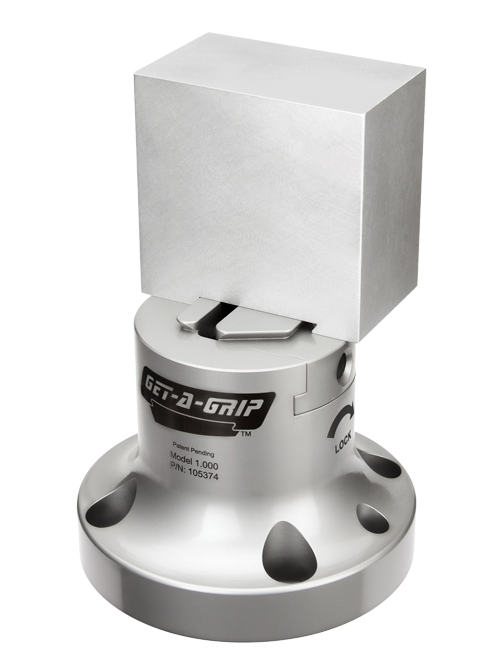

The recommended maximum workpiece is 5″ x 5″ x 5″ for Get-A-Grip Size 1.000 when using a single fixture. It is possible to hold a larger workpiece when using multiple fixtures as shown.

Raw Material shown cut in half to illustrate internal details

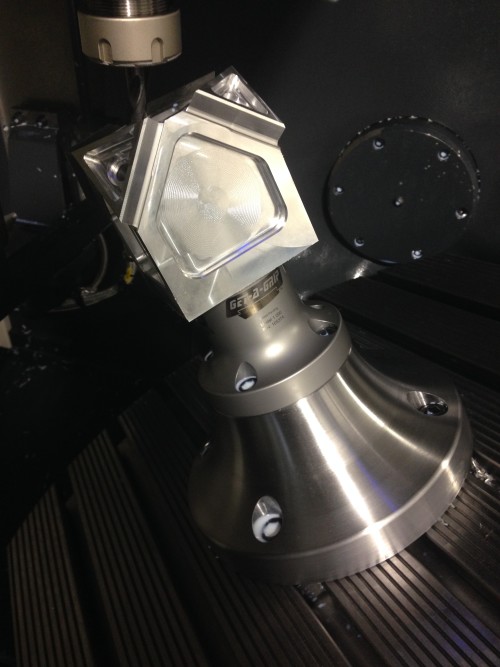

Get-A-Grip shown in DMG MORI DMU50 5-Axis Machining Center

Multiple Get-A-Grip Fixtures used to hold a large part (4″ x 4″ x 16″)